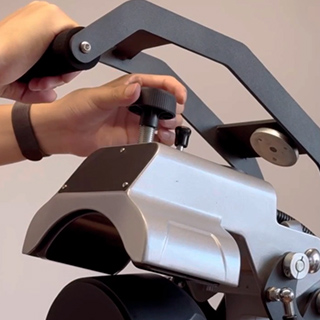

The Heat Press Leader brand manual hat heat press adopts a sturdy metal body and curved heating plate design. The surface of the heating plate is treated with Teflon coating, which is resistant to high temperatures and easy to clean. The machine is equipped with digital temperature and time control functions, which can accurately set process parameters according to different hat materials. Its core components include heating plates, pressure adjustment knobs, temperature gauges and timing dials, etc. The structure is simple and clear, and the operation is intuitive and easy to learn. The overall design is compact and occupies a small area. The folding machine arm is combined with the knob pressure adjustment. When using it, you only need to manually rotate and adjust to obtain uniform pressure and temperature control, which meets the needs of novices to get started quickly.

Embroidery patch printing: suitable for fixing embroidery labels and patches on the front of the hat by heat pressing. After heat pressing, it is firmly attached and has a three-dimensional effect. Heat Press Leader's double-sided heated hat machine can heat the front and back of the hat at the same time, which is particularly suitable for pressing embroidery patches and badges to make the pattern flat and fit.

HTV thermal film: suitable for transferring text or patterns on cotton or blended hats. Place the cut thermal film pattern on the hat surface, adjust the parameters and heat press transfer, easy to operate and delicate effect.

Sublimation printing: suitable for light-colored hats made of 100% polyester, which can achieve photo-level color pattern transfer. You need to use a polyester sublimation blank cap, set the time and temperature according to the material instructions for heat pressing, and you can get a high-saturation sublimation effect.

Other materials and hat types: The machine is compatible with mainstream hat types in the market (such as baseball caps, trucker caps, bucket hats, etc.) and common fabrics (cotton, blended, canvas, etc.), ensuring that different hat types and materials can get good transfer effects. Precise temperature and pressure control enables it to flexibly respond to the process requirements of various materials.

Preheating the hat body: Before the first use, place the empty hat on the heating plate for a few seconds to preheat it to remove moisture and wrinkles inside the hat, which will help improve the uniformity of the transfer. The heating plate can also be preheated to the target temperature in advance to ensure that heat energy can be conducted instantly to avoid insufficient heat.

Positioning and fixing of patterns: Place the designed patterns, letters or stickers on the corresponding position of the front piece of the hat, and use special high-temperature resistant tape for hot pressing to fix the pattern around to prevent the pattern from shifting or rolling when pressurizing. When aligning, you can use laser location system to align the pattern.

Adjust the pressure evenly: According to the thickness of the hat and the size of the pattern, rotate the pressure adjustment knob to make the heating plate fit tightly with the hat surface but not squeeze it too much. Try to keep the hats neatly placed during manual operation, otherwise it is easy to have local pressure that is too high or too low. If the pressure is uneven, it will cause incomplete transfer or the edge of the pattern to curl up.

Use a protective pad: A layer of anti-sticking cloth or Teflon cloth can be placed between the hat surface and the pattern to prevent the heating plate from directly contacting the pattern and prevent the film from burning or the pattern from sticking due to high temperature. At the same time, the protective cloth can also protect the hat surface from being burned by the hot plate.

Partitioned or multi-stage heat pressing: For patterns with a large area, you can first partially press a part, then adjust the position after the hat cools down to heat press the remaining part. Segmented operation helps to ensure the flatness of the pattern. In addition, after each heat pressing, let the hat cool down for a few seconds before removing the backing paper to improve adhesion.

Q: What hat types and materials are suitable for the hat heat press machine?

A: The machine is compatible with a variety of hat types (such as baseball caps, duckbill caps, bucket hats, etc.) and common fabrics (cotton, polyester blends, canvas, etc.), which can meet different customization needs. Its precise temperature and pressure control system supports the printing and pressing process of various materials, which can effectively adapt to various hat styles and transfer media.

Q: How to set the time and temperature of heat pressing?

A: You can refer to the instructions of the transfer material used to set the parameters. The Heat Press Leader model is equipped with a digital temperature and time display, which is very convenient to operate. Generally speaking, you only need to master the three elements of temperature, time, and pressure, select the corresponding parameters according to the material (such as embroidery patches, HTV, sublimation, etc.) and test them to get the ideal effect.

Q: Why does the pattern warp or not stick firmly during printing?

A: Common reasons are uneven pressure or insufficient temperature. It is recommended to check whether the pressure knob is adjusted to the appropriate gear to ensure that the heating plate is completely in contact with the cap surface; at the same time, use hot pressing tape to firmly fix the pattern. If the edge is still warped, try to extend the pressurization time appropriately or pressurize in batches to ensure uniform heat transfer.

Maintenance and Care Guide

Cleaning the heating plate: After each use, wait for the machine to cool down, and clean the surface of the heating plate with a soft, fiber-free cloth or anti-stick hot cloth to remove residual viscose or fiber. Keeping the heating plate clean helps stabilize heat transfer and extend the life of the equipment.

Check the fixings: Regularly check whether the pressure knob, hinges and screws are firm and not loose to ensure that the pressure adjustment mechanism is working properly. If any parts are found to be loose, tighten or replace the damaged parts in time.

Storage with power off: When not in use for a long time, turn off the power and unplug the plug, and store the device in a dry and ventilated place to avoid moisture and dust. When using, ensure that the power supply voltage is stable to avoid overload operation, thereby reducing the occurrence of failures.

The Heat Press Leader brand manual hat heat press has a compact design and excellent performance. It is easy to operate and has a wide range of applications. It can provide powerful support for hat customization for studios and novice entrepreneurs. Its precise digital temperature control, adjustable pressure and multi-functional compatibility make the transfer of various hat patterns more efficient and reliable. As long as it is properly operated and maintained, this machine will become a powerful tool for your personalized hat creation and escort your customization business.