Dual station electric heat press machine is a high-efficiency heat press machine designed for assembly line mass production. Through the alternating operation of dual station and all-electric drive, it realizes seamless and stable output, which can significantly improve the production capacity and product consistency. In this article, we will comprehensively explain how the dual station heat press becomes the core tool for assembly line production from the aspects of product introduction, technical specifications, advantageous features, application scenarios, operation points, FAQs and maintenance.

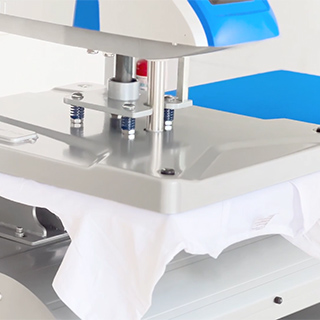

Dual station electric heat press adopts electric drive system, offering even pressure and heat without needing an air compressor. It supports continuous alternating operation, one side of the heating operation, the other side can be quickly placed to be pressed products, to realize the assembly line type production.

Dual station platennn: The heating platenn automatically slides between the two stations, ensuring that the operator always has one side in standby, greatly reducing downtime.

All-electric pressure system: replaces traditional pneumatic cylinders, eliminating the need for an air compressor, lower noise and easier maintenance; provides precise pressure control through the motor.

Digital touch panel: integrated temperature, time and pressure three-in-one control, support for multi-timer presets, intuitive operator interface, suitable for high-speed operation of the assembly line

Sturdy frame design: Ensure the stability of the machine body against bending and high-frequency vibration, adapting to the high-load continuous production environment.

| Model | B2-2N |

| Features | Electric | Twin Platens | Quick Platens | Curing |

| Voltage | 110V - 60Hz | 220V - 50Hz |

| Heat Platen | 16" x 20" | 40 x 50cm |

| Power | 1800W - 2200W |

| Controller | LCD Controller V3 |

| Max. Temp. | 232℃/450°F |

| Temp. Difference | ±4°F/2℃ |

| Power-off Preset | Max. 120 Mins |

| Max Timer Preset | 999 sec. |

| Max. Downforce | 300 g/cm² - 40 x 50cm |

| Pressure Setting | Digital Control |

| Accept Thickness | ≤4.5cm |

| Product Size | 91 x 57 x 70cm |

| Package Size | 110 x 83 x 87cm |

| Product Weight | 125kg |

| Shipping Weight | 140kg |

| Certificate | CE/UKCA (SGS Audited) |

The double-station alternating operation mode allows the operator to place clothes and patterns on one side while heating and transferring on the other side. Instant switching greatly improves production capacity, and the overall efficiency is increased by more than 50% compared to single-station machines.

The combination of all-electric drive and high-precision temperature control system, and the pressure distribution is uniform, which ensures the consistency and qualification rate of a large number of the same products. Compared with the pneumatic system, the electric system switches more quickly and responds more stably.

There is no need for air compressor and air line maintenance, only need to regularly fill the slide, guide column and other key components with high temperature resistant lubricant, and check the motor and screw tightness. The all-electric system reduces the potential for pneumatic valve and piping failure, making maintenance simpler and less costly.

Dual station electric heat press machine has an intelligent touch panel that supports temperature, time and pressure adjustments, as well as multi-timer settings. The machine is equipped with standby mode, which automatically cuts off the power supply when it is not operated for a long time to ensure safe and efficient operation.

T-shirt, sweatshirt, sportswear: suitable for DTF and sublimation heat transfer printing, dual-station mode ensures pattern saturation and washing resistance, suitable for large-volume orders and group customization.

Functional fabrics: sublimation transfer printing process for polyester sports fabrics to achieve full-color patterns in one piece, suitable for sports brand assembly line production.

Pillows, curtains, tablecloths: sublimation transfer of large-area patterns, temperature and time can be flexibly adjusted; dual-station design can meet the needs of rapid trial production of small batches and mass production switching requirements

Coasters, placemats, canvas bags: can achieve a variety of styles and materials customized, strong compatibility.

Promotional gifts: cell phone cases, mouse pads and other small products, dual-station high-repeat production to meet the requirements of production.

Parameter setting: Set the required temperature, time and pressure values on the LCD panel.

Place the sample: Place the product to be transferred on the lower platenn of the idle station and align the pattern position.

Start heat pressing: Press the start button, the heating platenn presses down on one side of the bottom platenn, and the machine automatically times and presses.

Switching stations: After the heat pressing is completed, the heating platennn automatically lifts and moves to the bottom platennn on the other side, and the station switching process is continuous and seamless.

Take out the finished product: Take out the transferred product, perform necessary cooling or post-processing, and then continue with the next one.

Temperature and pressure calibration: When using the machine for the first time and when switching between different materials, be sure to do sample tests and fine-tune the parameters first.

Anti-trap and anti-scald: Keep your hands and limbs away from the edge of the platennn during operation, and wait until the heating platennn is fully raised before picking up the parts; wear high-temperature-resistant gloves.

Environment check: Make sure the power supply is stable, the working area is free of obstacles, and the slide and guide are clean and regularly lubricated.

Q1: What is the difference in efficiency between a dual-station heat press and a single-station heat press?

A1: Dual-station heat press can realize alternating operation and uninterrupted production, with at least 50% efficiency increase, and can support higher frequency capacity demand.

Q2: How to choose between electric system and pneumatic system?

A2: Small-scale or frequent switching process is recommended to be driven by electric, no air source and fully automatic; large quantities, heavy pressure demand can choose pneumatic system, the pressure is greater and more stable.

Q3: How to avoid electric pressure system failure?

A3: Keep the screws tight and lubricate the motor screw assembly regularly; avoid overload operation and use a stabilized power supply

Q4: Do I need to recalibrate the parameters when switching materials?

A4: Yes, the temperature, time and pressure required for thermal transfer printing varies among different materials, so it is recommended to save them after testing them one by one.

Regular cleaning of the heating platennn: Use appropriate cleaners and a soft cloth to remove adhesive residue and dirt to maintain the efficiency of heat conduction.

Check and lubricate the slide rails: Fill the slide rails and guide columns with high-temperature-resistant lubricant every week to prevent jamming and rattling.

Tighten mechanical connections: Check the tightness of bolts, nuts and motor mounting every month to avoid loosening leading to bias pressure.

Calibrate the temperature control system: temperature calibration is performed every six months or after replacing key components to ensure accurate temperature display.

Electrical and Drive Inspection: Regularly inspect motors, cables and controllers to troubleshoot abnormal noise or vibration and ensure system stability.

The dual station electric heat press machine realizes high efficiency, stability and intelligence in assembly line type production through the core design of alternating dual stations, all electric drive and digital touch control. Whether it is customized clothing, home gift production, or industrial heat pressing process, this machine can provide excellent capacity and consistent quality. As a leading heat press company, we offer top-tier machines that give you a strong boost in the fierce market competition, becoming the core tool of assembly line production!