Manual heat presses are often preferred by studios in the early stages of heat transfer production due to their simple structure, low cost and easy maintenance. In this article, we will start from the basic characteristics of manual heat presses, discuss their five major advantages and disadvantages, and combine them with practical experience, FAQs and maintenance recommendations to help you scientifically assess whether it is suitable to purchase such equipment.

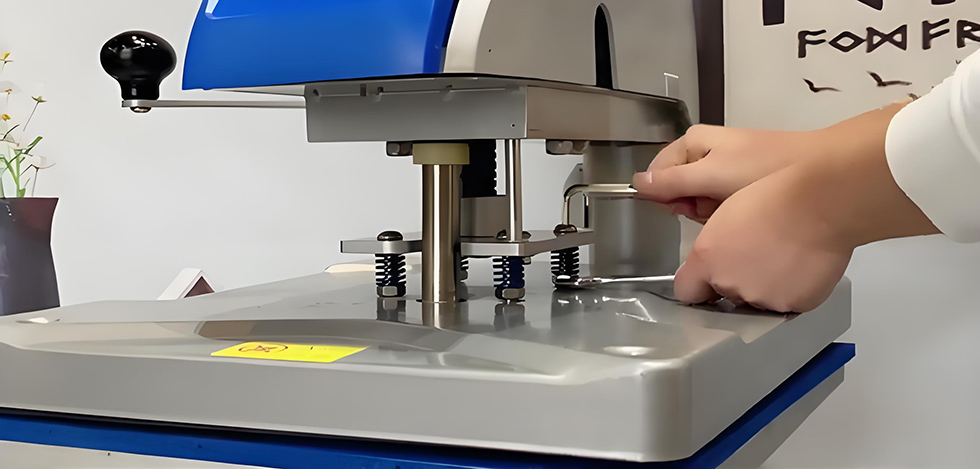

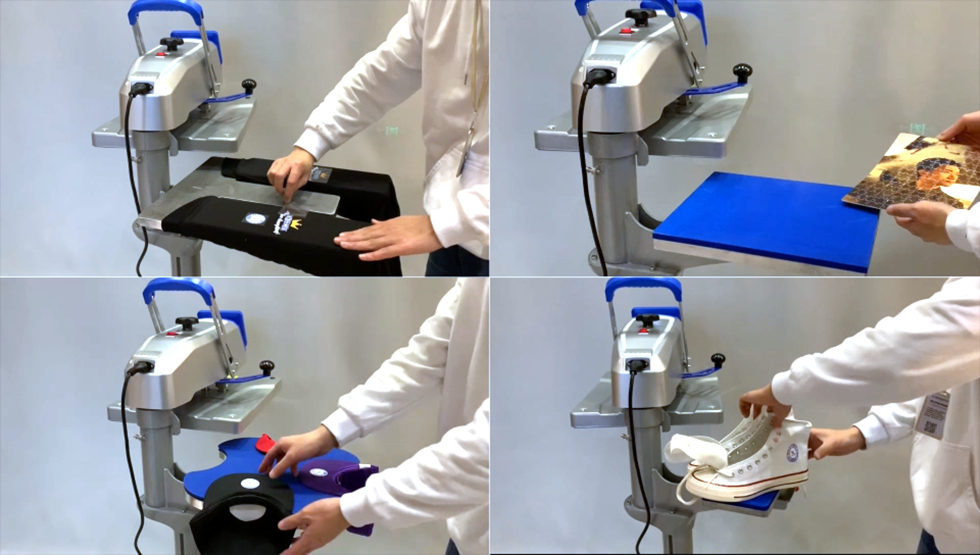

Manual heat press, also known as Clamshell or Swing-Away manual heat press, performs heat transfer printing by manually closing the plate and adjusting the pressure with a knob, which is suitable for personalization of T-shirts, canvas bags and other products. The core components include a heating plate, a pressure knob, a timer and a temperature control meter, and the entire process relies on the operator's experience in setting parameters and closing the plate.

The initial purchase cost of a manual heat press is relatively low, mostly in the $200-$500 range, making it suitable for studios or individual entrepreneurs with limited funds.

The structure of the machine is intuitive, and the operator only needs to master the three elements of temperature, time and pressure to get started, without the need for a gas source or an electric drive system, and with a short training cycle.

The clamshell model is compact and can be placed on a tabletop or mobile trolley, making it suitable for home studios or trade show floors where space is at a premium.

No air circuit system and complex motor, only need to clean the heating plate and check the pressure knob daily, there is no cylinder seal leakage or motor failure and other high maintenance expenses.

In addition to conventional flatbed printing, with small size desktop accessories, can also be completed cups, phone cases and other small pieces of transfer printing, applicable processes covering HTV, DTF and part of the sublimation.

Uneven pressure and manual errors rely on manual knobs or levers to apply pressure resulting in a lack of pressure uniformity and stability, making it easy for poor transfers and peeling edges to occur.

The single station requires manual platen closing and material placement, which leads to fatigue during long hours of operation, and the production capacity is only half or lower than that of the double station model (about 30-40 pieces/hour).

Most manual models are only equipped with a single heating plate, which is unable to realize rapid and uniform heating and temperature zoning control, and is prone to localized loss of temperature when transferring large-area or curved products.

Operators need to monitor the whole process, in the event of neglect or improper operation, there is a risk of scalding and product damage.

Manual models are difficult to integrate with assembly lines or duplex models, and are not suitable for medium to large-sized orders, and dual station or automation equipment needs to be invested in if the scale is expanded at a later stage.

Q1:How to test whether the pressure of manual heat press is even?

A1: You can use the “paper test” method, in the heating plate and the material between the printing paper, adjust the pressure of the paper should be able to draw smoothly and does not fall off. If there is a difference in resistance, you need to fine-tune the knob until the pressure is even.

Q2:What should I do if the temperature setting deviation is large?

A2: Use a digital thermometer or thermal strip to calibrate the surface temperature of the heating plate, and fine-tune the temperature control table according to the actual readings to ensure that the actual temperature and the set temperature error ≤ ± 5 ℃.

Q3:Is it suitable for manual heat press to transfer large size pattern?

A3:Large area patterns are prone to color difference or residue due to uneven heating of the edges, so it is recommended to segment the heat press for several times to align the heat press or choose the rocker type model to achieve a larger space coverage.

Heating plate cleaning: After each operation, wait for the equipment to cool down, use a lint-free cloth and special cleaner to wipe to prevent the accumulation of residual glue affecting heat conduction.

Pressure knob lubrication: Add a small amount of high-temperature resistant lubricant to the pressure knob and lever hinge every month to maintain smooth operation and prolong mechanical life.

Temperature control calibration: Carry out temperature calibration every quarter, use digital thermometer to test and adjust the controller at multiple points to ensure accurate parameters.

Machine Inspection: Regularly check the power cord and plug to ensure that there is no wear and tear or looseness; if there is any abnormal noise or poor heat dissipation, contact the manufacturer or professional overhaul in a timely manner.

With the advantages of low cost, ease of use and simple maintenance, manual heat presses are suitable for small-scale or start-up studios for personalization. However, it also has limitations in front of mass production and high-precision demand due to disadvantages such as uneven pressure, limited efficiency and lack of automatic protection. In case of subsequent business expansion, it is recommended to combine with a dual-station or automated heat press to realize a more efficient and stable production process.